The Realbull tailstock is, in comparison to the Sieg model, massive. It weighs about 10 lbs and sits on a 1/2″ thick cast iron base and comes with a substantial cam-lock. All as part of the design.

The flaw in this design is the lack of adjustments to align the tailstock to the headstock spindle. In short aligning this tailstock has been an exercise in frustration.

This frustration caused serious inspection of the tailstock which revealed some issues that should have prevented this lathe from leaving the factory but, of course, didn’t. This article discusses these issues in depth and shows how the shortcomings were fixed to produce an excellently operating tailstock.

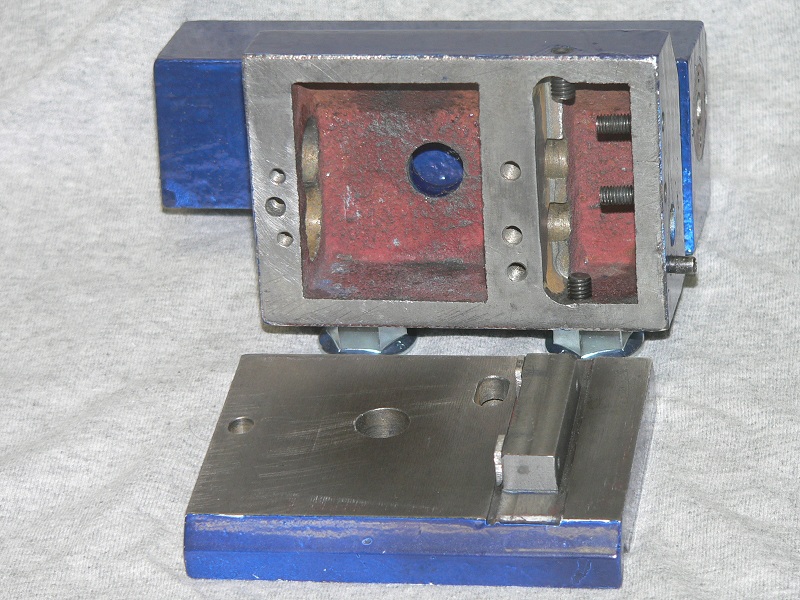

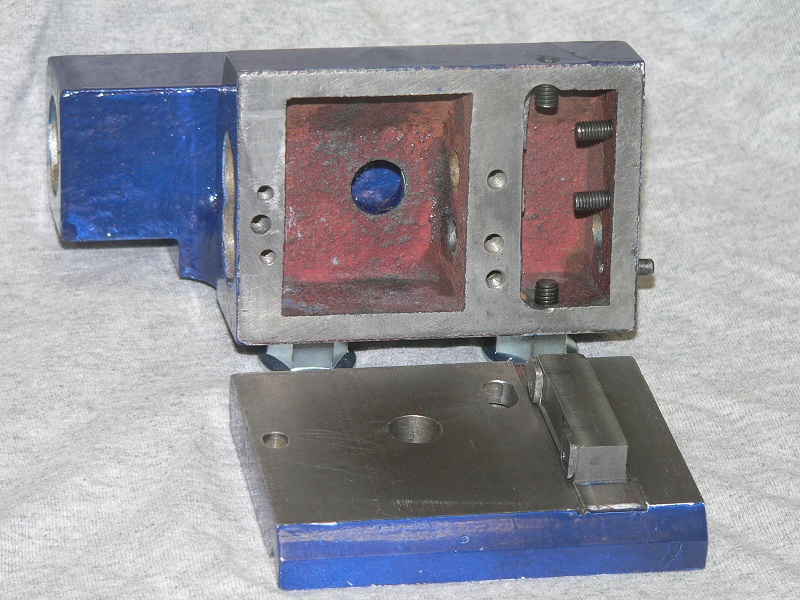

Although the picture above does not show it clearly, block “2” is about 1/2″ taller than the rest of the base. The picture also shows four adjustment screws “1”. The two on the right (angle screws) are intended to push the block “2” against the inner bulkhead of the upper casting or body and the front/back screws (traverse screws) set the body’s front/back depth. Once aligned the socket head cap screw “3” secures the base to the tailstock body in the threaded hole “4”.

A traverse or offset of the tailstock is accomplished by loosening the two angle screws and adjusting the traverse screws by equal amounts and retightening the angle screws.

Given this arrangement, it should be fairly easy to align the tailstock to the headstock, but there are several issues that are not yet resolved.

- There is no provision for vertical alignment of the tailstock. This is not impossible to overcome with shims and their use is probably a better solution.

- The block on the base is not “finished” in any meaningful sense of the word.

Because the block isn’t finished moving the body throws out all other adjustments. If the block were ground square (and perpendicular to the “V” on the bottom) such adjustments and movements would be possible with predictable results. - The slot for the lockscrew is inaccessible when the tailstock is mounted. Notice in the picture of the base above the slot for the lockscrew. Inexplicably, this lockscrew cannot be accessed while the tailstock is mounted on the lathe as that portion of the tailstock rides on the rear bedway. So once the tailstock is aligned, you would have to hang the tailstock at least halfway off the back of the bed to lock it down risking the adjustment.

- For the body to move relative to the base without disturbing the tailstock’s height the top of the base must be in a parallel plane to the rear flat of the bed.

Realizing the last requirement I set out to measure how flat the base was.

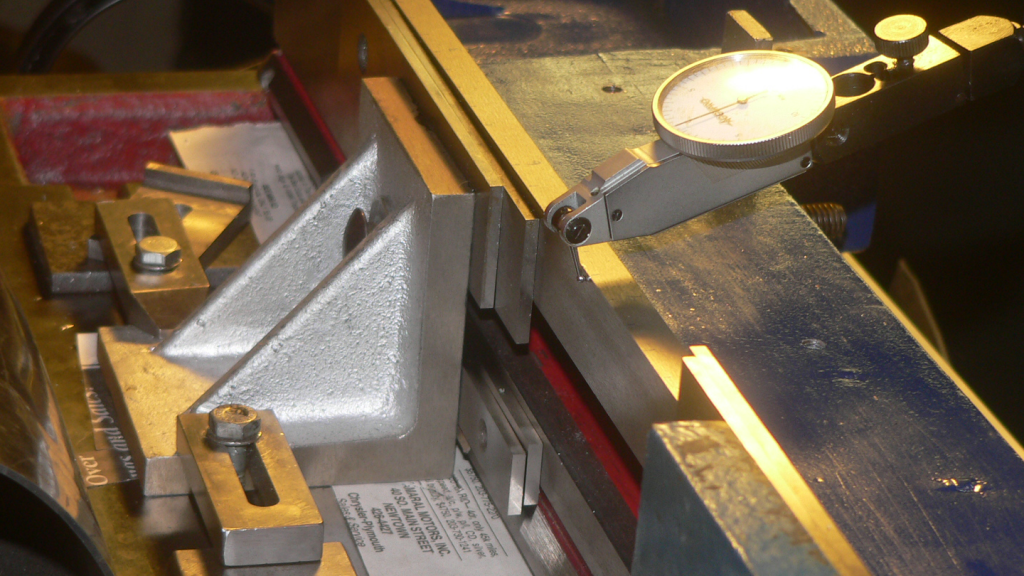

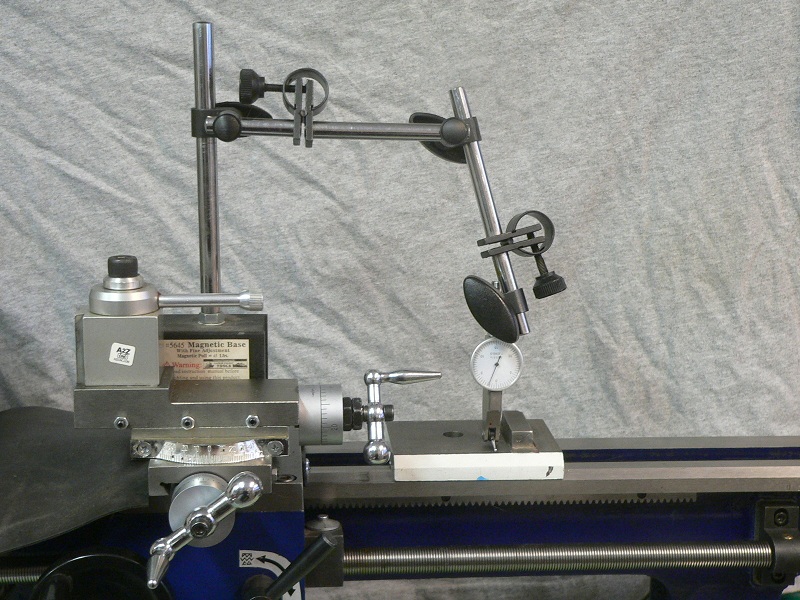

The setup was simple since the flatness relative to the bed is the important criteria. A DTI was placed on the carriage and touched to each of the tailstock bases’ four corners.

As you can see flatness is not great! There is a total of 18 thousandths from the front left corner to the back right corner. There seems to be a rise of 2-4 thousandths along the X-axis as you move away from the headstock and there is 14-16 thousandths rise along the Y-axis front to back.

I’d like to measure the bottom of the body as well, but can’t figure out what to use as a reference. Please make any suggestions in the comments.

Assuming that the tailstock body is fit to the base in it’s “normal” position it is entirely possible to align the tailstock for the normal position. The non-planar nature of the top of the base is a problem if one actually wants to use the offset feature of the tailstock as this design appears to allow.

In this case there is a run of about 8 thousandths per inch across the base, and the traverse screws are about 1/2″ long, there will be a vertical change of 4-5 thousandths in using the offset feature of the tailstock.

From the normal or centered position, the tailstock will gain or lose 0.002″ vertically. While this is acceptable for some applications this shows another instance of this lathe not really being ready for use as it left the factory.

The ideal resolution would have been to regrind the surface flat, grind the baseblock to a correct angle relative to the “V” on the base and regrind the tailstock body. Unfortunately I did not have access to a surface grinder so such an extensive fix was not realistic.

It is notable that regrinding as a fix would probably leave the tailstock well short of meeting the vertical height of the spindle. Assuming that 12-15 thousands would have to be removed from the base AND the body it’s not hard to imagine the tailstock being vertically under the spindle axis by 0.030″. This could be shimmed but the shims would interfere with any offset operation making the entire effort of fixing the tailstock pointless.

In the end, I decided to leave the base and body alone and that one aligned the tailstock would never be offset.

In summary the base is not flat, the base block that dictates the angle is not smooth and it’s difficult to determine what surfaces are mating, and it’s difficult to lock in a setting since the lockscrew is inaccessible when the tailstock is mounted on the lathe.

With these issues in mind planning was started for a milling session on the base with the following objectives

- Create a lock nut in the front of the tailstock: There’s plenty of room on the front bulkhead for another lockscrew, right in the middle where you can reach it from underneath the bed.

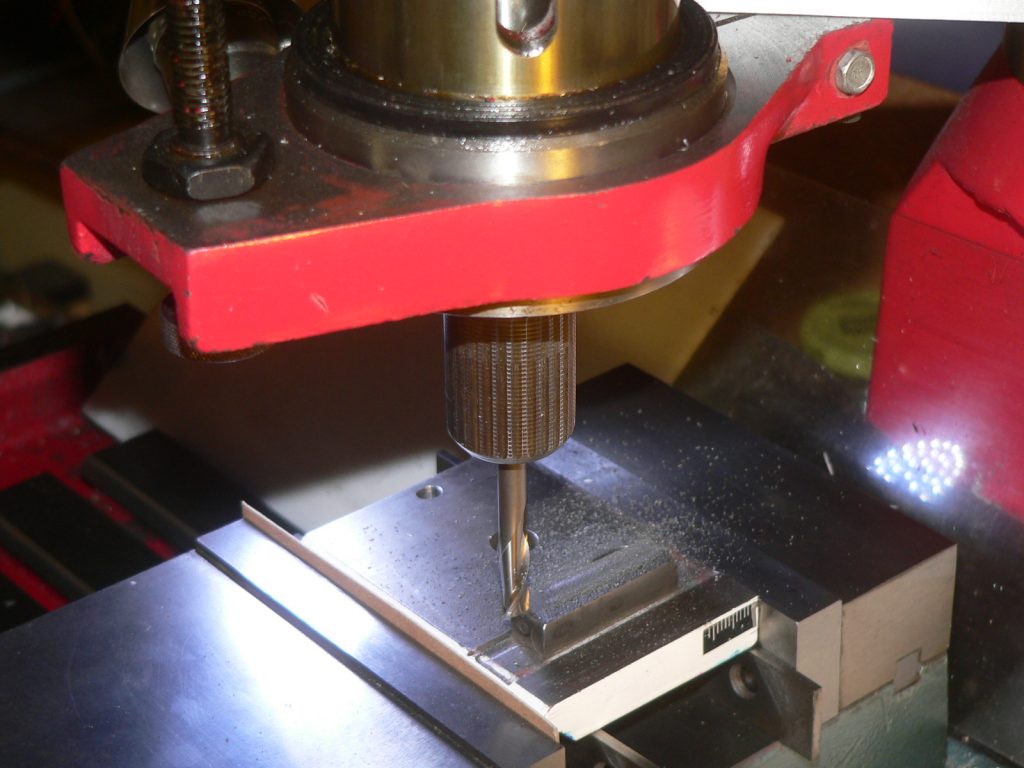

- Recess the front center of the block so that it makes contact at the outside edges: This would reduce the contact area making the angle easier to control. The recess is minimal, about ten thousandths or so.

- Reduce the height of the block: While there was likely sufficient room the top of the block was uncomfortably close to the cam lock driver. Since the base was already being milled, it was easy to remove about 0.012″ and ensure nothing was going to rub.

With these modifications made, it became very simple to bring the entire tailstock within 0.004″ in any plane or rotation of interest. When trying to make it better than that, things became unreliable again.

Note: The blue tailstock is not a replacement but the original tailstock. While I had the tailstock all cleaned from the milling operation there was a several days reprieve from the cold here in New England so the opportunity was taken to paint it to match the bed. Turns out white is a terrible color for a machine tool.

At this point attention was turned to the tailstock body. In particular the contact area of the inner bulkhead. When the base block had been recessed to set the contact surfaces the body’s bulkhead area was smoothed by file. When problems persisted in alignment the body was inspected again and it was realized that the bulkhead contact wall is not perpendicular or at an acute angle to the base block. As a result; when the angle screws are tightened the tailstock body raises AWAY from the base. If the wall were at an acute angle the force would be downward reinforcing the angle screws tension.

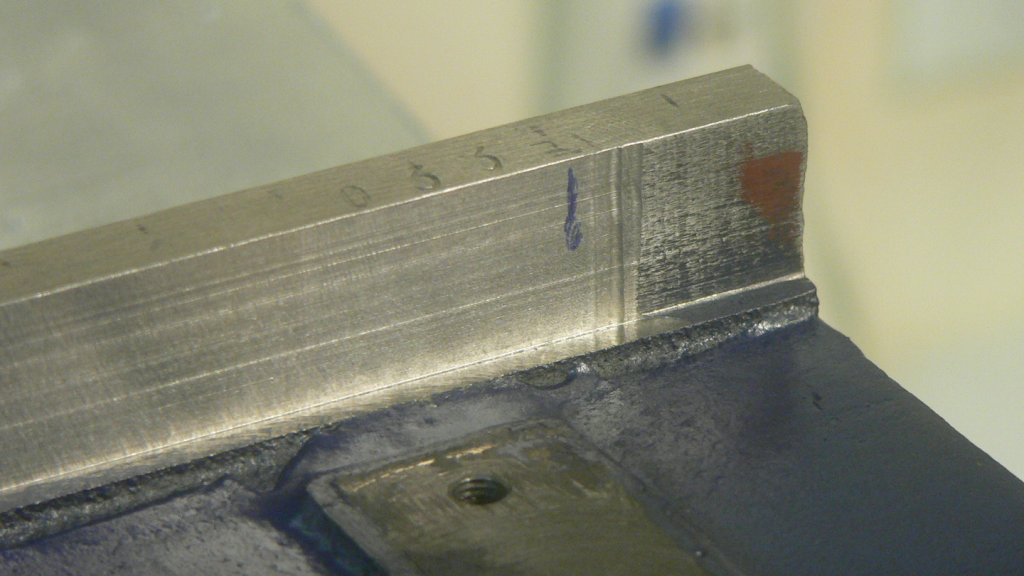

So after identifying this issue with the body the tailstock body and base were taken back to the mill. The bulkhead was measured as being about 5 degrees off perpendicular to the base. The tailstock body was milled to make the bulkhead perpendicular to the bottom and the base block was again milled to resquare the block on both the bulkhead mating surface, with a 0.025″ relief in the center. I also ensured that the ends of the block were squared to mate with the traverse screws in the body. This next picture shows the results.

Why was the bulkhead at a 5 degree angle? I can honestly say I do not know. My best guess is that it was an error at the factory. I’d be very interested if anyone else with this style of tailstock could look at this feature and let me know the angle of their bulkhead.

By the time that was done about 0.040″ had been removed between the block and the bulkhead. This meant that the tailstock body would sit further back on the base. Since the base is NOT planar (refer to discussion earlier) I did not want the body shifting this much so I was going to need some fairly thick shims. I also wanted to be able to control the angle so I tapped 3×0.5 mm into the base block and made thick shims with a countersunk 3mm screw. The 3mm size was the smallest countersunk screw I could find on a Sunday afternoon at the local hobby shop. This next picture shows the base block shims fairly well.

So this story is finally winding down to the end. With all these modifications, I was easily able to get the alignment within 1.5 thousandths. I still noticed a tendency for the body to rise away from the base when using the traverse screws, but the angle screws now worked just as expected.

I have not looked carefully at them, but I suspect that the traverse screws are not tapped perpendicular to the body so there is some upward force. It was not nearly as bad as the angle screws before fixing the bulkhead and was easily compensated for. Should the base have to be returned to the mill at some future date it would make sense to consider milling the end faces of the base block to an obtuse angle to the base. This would have the effect of forcing the body down as previously discussed.

For a tailstock on this class of lathe 1.5 thousands is not bad but I wanted to see how far I could dial it in.

The final issue came when tightening down the lock screws on the bottom of the base. It was very easy to throw the alignment out by 4-5 thousandths during tightening. Fortunately, this turned out to be very repeatable and predictable so I took careful note of the direction of misalignment and compensated to the other side. By using this method and carefully adjusting the torque on the lock screws, I was, in the end able to get the tailstock with 0.0005″ (yes that’s a half thousandth) with the tailstock ram retracted and extended. Alignment beyond that is beyond both my ability to measure and my patience.

The general design of this tailstock is better than the traditional Sieg design. The increased mass of the tailstock, the hefty camlock mechanism with nice features such as a detent in the lock position, handle tension adjustment, and oil ports make me look favorably upon the tailstock itself.

Perhaps I simply received a bum unit but the non-planar nature of the base, the bulkhead being off angle, no ability to lock down the front of the tailstock and the difficulty I had in being able to adjust it out of the factory would be enough to give most people fits. It is an unfortunate testament to the lack of quality control and certainly not a fitting execution of an otherwise admirable design.

If I received another of these units, I would immediately check the flatness of the base and the bulkhead angle again. I suspect that while the bulkhead may have been an error, my feel is that the base is never flat or parallel to the ways. Again, I would be very interested to know the results should anyone ever measure this. Had the bulkhead angle been correct to start, I probably would have been able to adjust the tailstock to an acceptable level without modification at all.

Even if the tailstock came perfect I would also immediately add the front lockdown screw slot. It seems a simple thing, but in the final adjustments this was very helpful. When the lockdown was tight, the angle tended to be adjusted more than a traversing move and visa-versa. This was the motion that let me dial in the final adjustments as finely as I did.